Why do I need to wash?

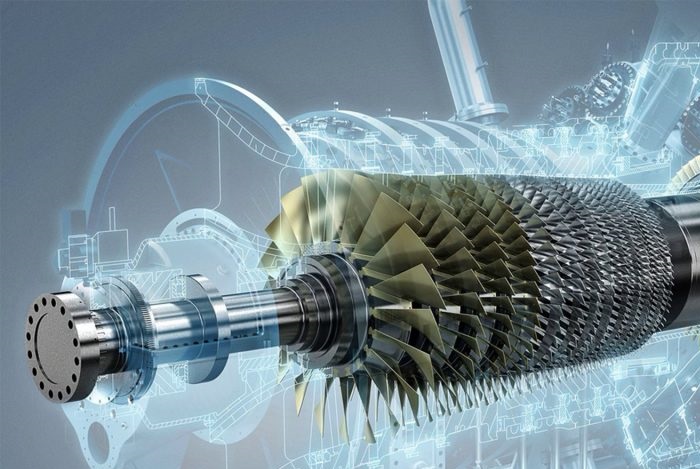

The compressor of a gas turbine ingests a large amount of air. This air (even when filtered), contains contaminants which are deposited on the compressor blades and stators.

These deposits build up, eventually leading to a reduction in compressor efficiency.

Compressor washing removes this deposited fouling, restoring the aerodynamic profile and compressor efficiency.

A reduction in compressor efficiency causes an increase in fuel consumption; an increase exhaust gas temperatures (EGT) and reduced power output.

Online cleaning (‘HOT’Washing)

Performed with the gas turbine operating and under load. It maintains compressor efficiency after offline washing, minimizing power losses. Online cleaning also extends the operating period between shutdowns.

Online cleaning is generally recommended every three days to weekly.

Operating and local environmental factors will determine the appropriate wash regime.

Offline cleaning (‘COLD’ Washing)

Performed with the engine shutdown. Restores maximum power and efficiency.

Off-line cleaning is a more thorough process than on-line cleaning due to both the greater volume of cleaning solution that is passed through the engine and the much greater dwell (soak) time for the cleaner to work.

Offline cleaning is generally recommended three to four times per year.

Operating and local environmental factors will determine the appropriate wash regime.

On-line Washing – PROS

- Increases operating periods between Off line washes

- No waste disposal required (fully consumed during cleaning)

- No shutdown required – No loss of revenue

On-line Washing – CONS

- May not fully clean all compressor stages

- Must use pure water for wash and rinse

Offline Washing – PROS

- Maximum power recovery

- Cleans entire compressor section

- Good Quality water (potable) may be used for wash and rinse

Offline Washing – CONS

- Requires complete engine shutdown and cooling period.

- Potential loss of revenue • May not be convenient (availability)

- Waste requires careful disposal, according to local regulations

Compressor wash fluid is commonly heated (especially for on-line washing). Heating specifications can be obtained from the engine manufacturers’ maintenance manual.

Categories: blog

Tags: #power, #consumables, #turbines, #ZOKGhana

Source: ZOK International

Author: NANA YAW ODURO-FREMPONG

Date: JUNE 01, 2020